From manufacturer with best durability,Factory Offer!!! Full-automatic Horizontal Paper Scrap Baler Press

Basic Info

Model No.: BJWQ-150

Product Description

Specifications

Full-automatic horizontal paper scrap baler press:

1. No-human operation

2.Suitable for site work

3.Auto ejecting bale

Product Description

Full-automatic horizontal paper scrap baler press

The full-automatic horizontal paper scrap baler press is specially used to packaging many kinds of loose material, such as cotton yarn, cotton waste, tobacco, plastic, wool top, cocoon, silk, grass, straw, hay, cardboard boxes, plastic bag etc. With stable and durable design, the machine is suitable for site work.

Bale weight and length of this auto-tie horizontal baler can be programmed and controlled through a simple and easy to use touch screen panel according to your specific transportation arrangement, making it ideal to maximize your container loading.

Features of full-automatic horizontal paper scrap baler press :

Equiped with PLC system and a series of sensors, full automatic from feeding, compressing, automatic wire strapping and cutting, to bale ejection once the bale length reaches the set value;

Auto alarm system, protect both machine and users, the error details and soluction will be provided on touch screen

Unique cooling system, cooling down the temperture of the hydraulic oil;

Adjustable bale length from 500-2100mm;

One button operation, enables compressing, bale ejectin and bagging a continuous, efficient process, saving your time and reducing your cost.

Main technical data of full-automatic horizontal paper scrap baler press:

| Model | BJWQ- 40(this model) | BJWQ-60 |

| Capacity | 6-10 bales/hr (1-3tons/hr) | 8-12 bales/hr (2-4tons/hr) |

| Motor power | 18-22KW | 22-30KW |

| Pressure | 40tons | 60tons |

| Bale size | W720*H720mm(Length is adjustable) | W850*H750mm |

| Bale weight | 200-400kg | 300-500kg |

| Bale density | 300kg/m3 | 350kg/m3 |

| Feeding chamber size | L1000*W720mm | L1200*W750mm |

| Wire quantity | 12# steel wires*4 | |

| Working method | Full auto feeding, pressing, wire binding | |

| Control way | PLC control | |

| Weight | About 8 tons | About 10 tons |

| Model | BJWQ-80 | BJWQ-100 |

| Capacity | 8-12 bales/hr (4-7tons/hr) | 8-12 bales/hr (8-10tons/hr) |

| Motor power | 30-45KW | 45-60KW |

| Pressure | 80tons | 100tons |

| Bale size | W1100*H800mm(Length is adjustable) | W1000*H1000mm |

| Bale weight | 400-600kg | 600-1000kg |

| Bale density | 400kg/m3 | 500kg/m3 |

| Feeding chamber size | L1500*W800mm | L1800*W1000mm |

| Wire quantity | 12# steel wires*4 | 10# steel wires *5 |

| Working method | Full auto feeding, pressing, wire binding | |

| Control way | PLC control | |

| Weight | About 13 tons | About 17tons |

| Model | BJWQ-120 | BJWQ-150(this model) |

| Capacity | 9-13 bales/hr (9-12tons/hr) | 9-13 bales/hr (12-15tons/hr) |

| Motor power | 60-75KW | 75-90KW |

| Pressure | 120tons | 150tons |

| Bale size | W1100*H1100mm(Length is adjustable) | W1100*H1100mm |

| Bale weight | 700-1200kg | 900-1400kg |

| Bale density | 600kg/m3 | 720kg/m3 |

| Feeding chamber size | L2000*W1100mm | L2400*W1100mm |

| Wire quantity | 10# steel wires*5 | |

| Working method | Full auto feeding, pressing, wire binding | |

| Control way | PLC control | |

| Machine weight | About 20tons | About 28tons |

| Model | BJWQ-200 | BJWQ-250 |

| Capacity | 18-22tons/hr | 20-25tons/hr |

| Motor power | 90KW | 90KW |

| Pressure | 200tons | 150tons |

| Bale size | W1100*H1100mm(Length is adjustable) | W1100*H1100mm |

| Bale density | 900kg/m3 | 1000kg/m3 |

| Feeding chamber size | L2400*W1100mm | L2400*W1100mm |

| Wire quantity | 8# steel wires*6 | |

| Working method | Full auto feeding, pressing, wire binding | |

| Control way | PLC control | |

| Machine weight | About 20tons | About 23tons |

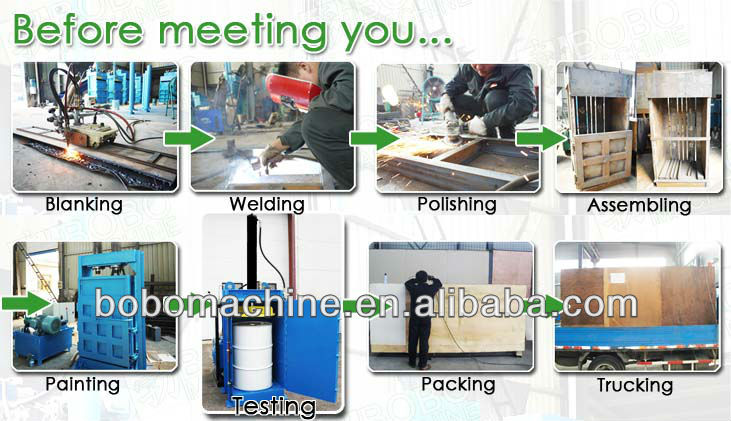

Packaging & Shipping

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long term cooperated forwarders who can handle the shipment smoothly.

Also we would like to have seamless cooperation with your forwarder at your convenience.

Our Services

1.Professional and patient consulting service to help you find the suitable solution.

2.Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3. Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4.Free training and accommodation in our plant during machine inspection. Or photos and video of the machine and

package for your confirmation before shipment.

5.Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6.For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7.For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at

original cost after that.

Company Information

BOBO MACHINE CO., LTD is the professional supplier for metal processing machinery in China. We supply the

Duct Machine, PU Foam Machine, Baling Machine, leather machine, wheel production line and different kinds of metal

processing machinery.

With many years successful industry experience, we have established long term cooperation with lots of customer from

all over the world. Also we have sales network in Britain, Russia, USA, Mexico and Brazil to supply the machine and

service in local market directly.Also we can work as your professional consulting advisor in China to sourcing the right

machine and equipment as per your requirements, to offer you the complete solution and necessary after sale service.

[Professional and creditable, customer first", with these work faith, we successfully win the expanded market and

favorable feedback from our customers, and we always look forward to be your reliable supplier and advisor in China, to

have a long term cooperation for mutual benefit.

FAQ

1. Q: What is the power supply of the machine?

A: The standard power supply in china is 380V, 3P, 50Hz. We also can customized accordingly.

2. Q: What information should the customer provide to get an accurate quotation from us?

A: The customer should provide the related technical requirements, drawings, pictures, industrial voltage,

planned output, etc

3. Q: What is the payment term?

A: The payment term is 30% down payment, and 70% before shipment(T/T mode), we also accept other payment term, like L/C, D/A, D/P etc.

4. Q: What is the delivery time?

A: Normally the delivery time of the machine is 40 days after receive down payment.

5. Q: What is the warrantee period of the machine?

A: The warrantee period is one year since the date of B/L.

6. Q: How to contact us?

A:Web: www.bobomachine.com

Skype: wood-bobomachine

Cell/Whatsapp:0086 13813647547

Tel/Fax:008651387630500

Contact us if you need more details on Hydraulic Paper Baler Press. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Abaca Fiber Bale Press、Carbon Fiber Press. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Baling Machine > Automatic Horizontal Baler

Premium Related Products