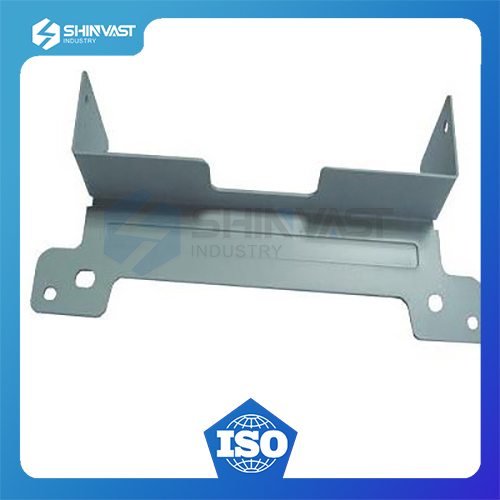

OEM sheet metal aluminum stamped parts

Basic Info

Model No.: SVI-164

Product Description

The separation process

Is a kind of basic materials used mould separation of stamping process, it can be directly made into flat parts or for other stamping processes, such as bending, deep drawing, forming, such as preparing blank, can also be carried out has on the stamping forming cutting, trimming, etc.Blanking is widely used in automotive, home appliances, electronics, instrumentation, machinery, railway, communication, chemical industry, light industry, textile, and aerospace industries.Cutting processing accounts for about 50% ~ 60% of the entire stamping processing operations.

Stamping Operations

Bending - the material is deformed or bent along a straight line.

Flanging - the material is bent along a curved line.

Embossing - the material is stretched into a shallow depression. Used primarily for adding decorative patterns. See also Repoussé and chasing.

Blanking - a piece is cut out of a sheet of the material, usually to make a blank for further processing.

Coining - a pattern is compressed or squeezed into the material. Traditionally used to make coins.

Drawing - the surface area of a blank is stretched into an alternate shape via controlled material flow. See also deep drawing.

Stretching - the surface area of a blank is increased by tension, with no inward movement of the blank edge. Often used to make smooth auto body parts.

Ironing - the material is squeezed and reduced in thickness along a vertical wall. Used for beverage cans and ammunition cartridge cases.

Reducing/Necking - used to gradually reduce the diameter of the open end of a vessel or tube.

Curling - deforming material into a tubular profile. Door hinges are a common example.

Hemming - folding an edge over onto itself to add thickness. The edges of automobile doors are usually hemmed.

Industry-specific applications

Metal stamping can be applied to a variety of materials based on their unique metalworking qualities for a number of applications across a wide range of industries. Metal Stamping may require the forming and processing of base common metals to rare alloys for their application specific advantages. Some industries require the electrical or thermal conductivity of beryllium copper in areas such as aerospace, electrical, and the defense industry or the high strength application of steel and its many alloys for the automotive industry. Industries Metal Stamping is used for:Aerospace,Agriculture,Ammunitions,Major appliances,Small appliances,

Automotive,Commercial,Construction,Electronics,HVAC,Lawn Care & Equipment,Lighting,Lock Hardware,Marine,Medical,Plumbing,Power Storage,Power Tools,Small Engine,

Photos of Sheet metal aluminum stamped parts

How to contact us?

Send your Inquiry Details in the Below, Click "Send" Now!

Product Categories : Stamping Parts > Aluminum Stamping Parts