high efficient hydraulic cans compactor machine

Basic Info

Model No.: JB serie

Product Description

Specifications

high efficient hydraulic cans compactor machine

1. Hydraulic driven

2. Vertical structure

3. Suitable for can recycle

Product Description

high efficient hydraulic cans compactor machine

The high efficient hydraulic cans compactor machine is suitable for compressing pop cans, oil drums, paint buckets, scrap aluminum yarn, aluminum skimming etc.

Feature of high efficient hydraulic cans compactor machine

Hydraulic driven for smooth work

The bale size can be customized

The bale weight can be customized

Front & Back Opening doors for convenient strapping and bale ejecting

Main technical data of high efficient hydraulic cans compactor machine

| Nominal force | Bale size | Bale weight | Capacity | Chamber size | Recycle time |

| 50ton | 300*300mm | 7-10kg | 6-10bale/hr | 300*300*1200mm | 25-30seconds |

FAQ

1. Q: Can you suggest a suitable model for me?

A: Yes. Just please tell us your bale size or bale weight, then we can check for you accordingly. Also we can customize the machine according to your special requirements.

2. Q: What`s the capacity of the baler?

A: we have many different models, which have different baling capacity. Also we can suggest the suitable model according to your capacity requirements.

3. Q: How much time it takes for one bale?

A:Usually, it takes 30-35s for one cycle, then the time needed will depend on manual feeding speed and baling speed.

4. Q: If the machine can use for baling different material, like as paper, carton, hay, straw, fiber, cloth, scrap metal, etc?

A: Generally speaking, we separate the Baling Machine for metal and non-metal materials. The non-metal material mainly as waster paper, cardboard, fiber, clothes, etc, and the metal materials including aluminum can, scarp iron, stainless steel, etc.

5. Q:Regarding your horizontal baling machine, could you please tell us the difference between full-automatic and semi-automatic?

A: Yes, the difference between them is: full-automatic bind wires automatically, but semi-automatic do this manually.

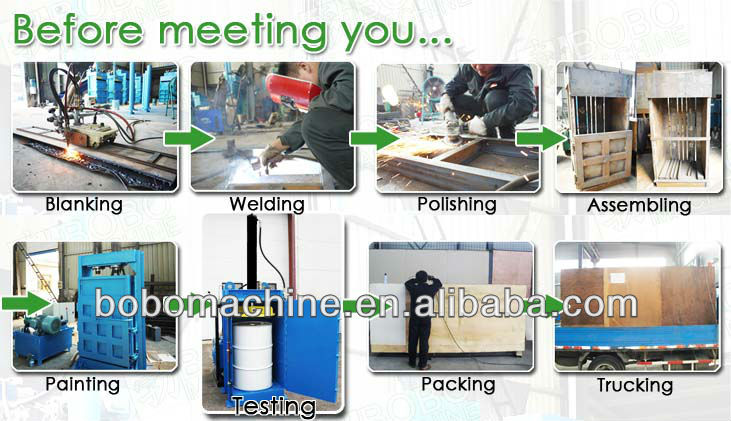

Packaging & Shipping

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like to have seamless cooperation with your forwarder at your convenience.

Our Services

1 Professional and patient consulting service to help you find the suitable solution.

2 Further negotiation about the technical details, machine configuration, price basis, payment term and delivery time.

3 Powerful control of the machine production schedule and quality, and keep you posted about details in time.

4 Free training and accommodation in our plant during machine inspection. Or photos and video of the machine and package for your confirmation before shipment.

5 Quick and safe shipment as per your requirement including the booking ,container loading, and shipping documents.

6 For technical support, we can help you online by email and phone, also we can send technicians to your site if necessary.

7 For the spare parts, we will supply the parts for free during one year guarantee period, also the parts supplying at original cost after that.

Company Information

BOBO MACHINE CO., LTD is the professional supplier for metal processing machinery in China. We supply the Duct Machine, PU Foam Machine, baling machine, leather machine, wheel production line and different kinds of metal processing machinery.

With many years successful industry experience, we have established long term cooperation with lots of customer from all over the world. Also we have sales network in Britain, Russia, USA, Mexico and Brazil to supply the machine and service in local market directly.Also we can work as your professional consulting advisor in China to sourcing the right machine and equipment as per your requirements, to offer you the complete solution and necessary after sale service.

[Professional and creditable, customer first", with these work faith, we successfully win the expanded market and favorable feedback from our customers, and we always look forward to be your reliable supplier and advisor in China, to have a long term cooperation for mutual benefit.

Contact us if you need more details on High Efficient Hydraulic Cans Compactor Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminum Can Press、Aluminum Can Baler for Sale. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Baling Machine > Aluminum Can Baler Series

Premium Related Products

Other Products

Hot Products

Enclosure sealing strip gluing machineHigh performance fiber spray machine with gunAutomatic pneumatic foam mouldingFT-G1200 Draught fan front disk flow forming machinehydraulic oval tubeformerBOBO FULL AUTOMATIC BARREL HOOP ROLL FORMING MACHINE0.8-1mm induction cooker Jumper wire bending machineBimetallic extruded finned tube making machineAutomatic copper capillary tube cut off machine with tube end forming processHVAC Standing S&D cleat slip and drive lockformer and rollformer machineTruck bedliner polyurea coating and spraying machinePolyurethane PU foam injection machine for hollow tire foam filling workHAVC spiro round galvanized duct tubeformer machineCondenser pipe machine for frezzer and air conditionerCNC heli coil forming screw stainless steel wire thread insert forming machineSteel clamp clip reinforced PVC / glass silicon / tarpaulin flexible duct machine